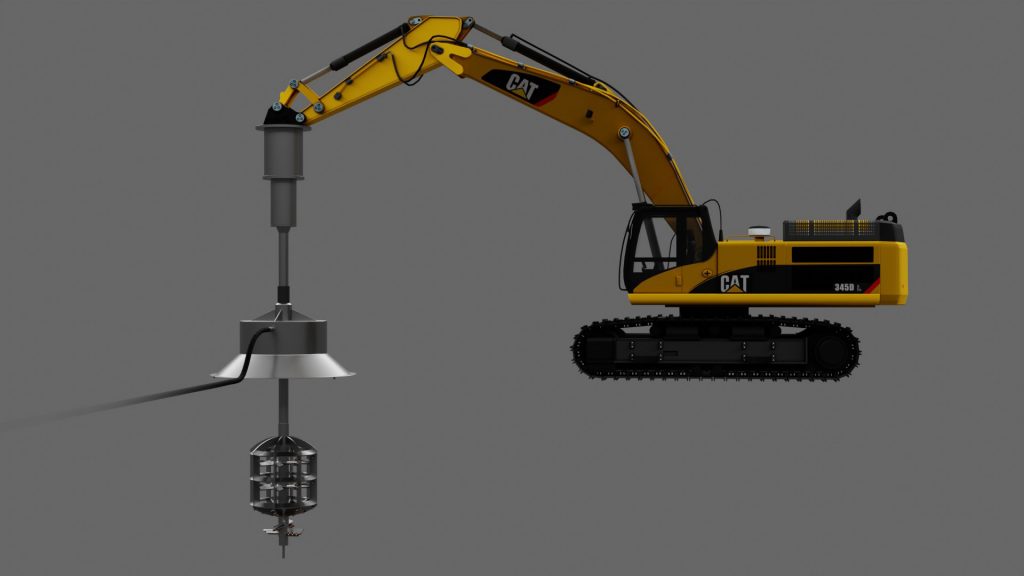

The Dome Covered Mixing Head has been especially designed to capture toxic fumes or unwanted smells that are impregnated into the soil structure, then released when the ground is broken/disturbed. These unwanted vapours are then continuously siphoned off via the flexible 100mm hose back to the Carbon Activated Filtration System.

The Dome Cover will sit on the ground under its own weight during mixing. Three small metal spikes will penetrate the soil to stop any potential spinning due to friction from the driveshaft. The Dome Cover slides up and down the drive shaft independently on a hardened plastic sleeve. This allows the driveshaft to turn independently from the Dome Cover and go up and down to mix the soil column. When moving the mixer to the next spot, the excavator will lift the whole mixer up off the ground and place it in the next spot. The Dome Cover sits on top of the heavy-duty mixing head when shifting occurs.

Binder delivery “Liquid Cement Grout” or similar goes down the “Driveshaft” under pressure, exiting from a “Exit Port” on the heavy-duty mixing head itself. This allows the “Binder/s” to be placed straight into the mixing zone. The grout is delivered from the fully automated Hany grout pump which is automatically feed directly from the Sami, 65-ton, horizontal, Cement Silo System. http://jpmarshall.co.nz/cement/mobile- silos/#main By using liquid cement grout over dry powder binders, this stops dangerous silica dust from drifting in the wind and exposing your staff, the public or going over the neighbouring buildings, cars etc…

The mixing head is 100% detachable using CFA Couplers.

The following reasons why it is detachable:

- For easy breakdown of the mixing head for transportation. The mixing head comes off

and securely placed into its own transport cradle for staff safety. - The Dome Cover can then be slipped off the driveshaft for easier transporting.

- The shaft can then be detached from the excavator and laid down.

- If the mixing head gets damaged or worn down (in need of hard facing) a second mixing

head can be quickly attached to keep the project working within 10 to 15 minutes.

Maximum mixing depth is 5.50m

Diameter of the heavy-duty mixing head is 1.40m

Torque of the drive motor is 90,000Nm

Recommended excavator 40- ton upwards

All images are covered under copyright for NZ Stirrers Limited.