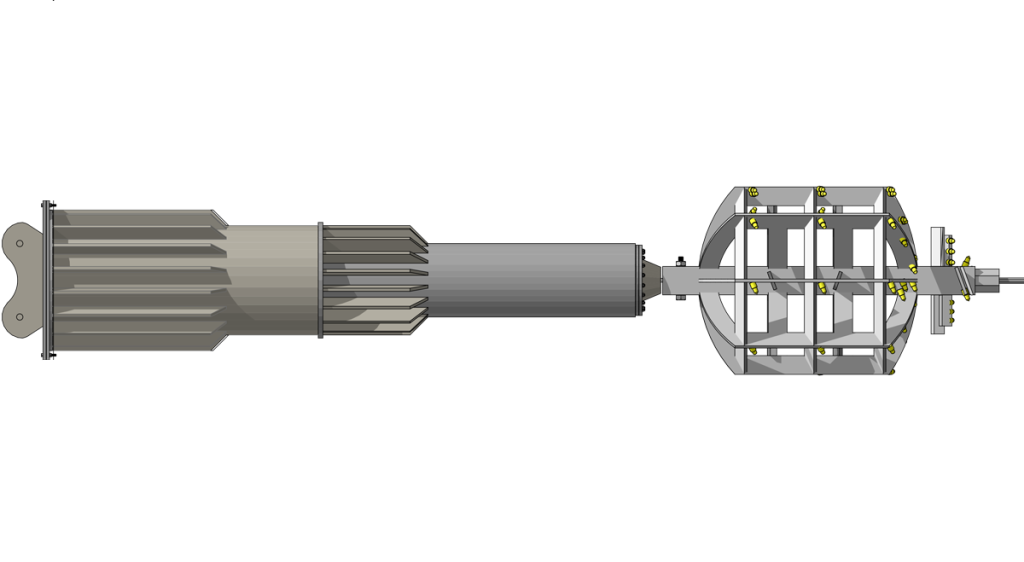

NZ Stirrers, Mass Soil Stabilization mixing heads are specifically designed to deliver liquid cement grout down through the centre drive shaft right to the mixing head or to the mixing zone. The cement grout exits out the “Port hole” of the Heavy-duty mixing head into the soil. This technology come about from the development of our Underwater In-situ Mixing System.

Having interchangeable mixing heads made from high tensile, abrasion-resistant bisalloy steel designed for tough soil conditions. The heavy-duty mixer comes with rock cutting teeth for breaking through the toughest soil conditions.

Using “CFA Couplers” to connect our mixing heads onto the end of the drive shaft makes it quick to change out a replacement mixing head if it gets damaged or needs to be hard-faced.

All of NZ Stirrers Mass Soil Ground Stabilizing Mixers use liquid cement grout as it’s main “delivery binder” reason is, so no staff are exposure to harmful silica dust. This is a world first, developed in New Zealand.

NZ Stirrers are more than happy to customize the whole mixing system to suit your project requirements also.

Powerful Drive Motors

We use a range of Italian made hydraulic motors that deliver between 90,000Nm and 120,000Nm of Nominal Rated Torque. Compare that with our competitor’s PMX Mixer which only has 12,000Nm of torque. Ground stalling then becomes a problem in anything other than the soft European Peat soils that it has been designed for. With our high torque drive motors, this resolves any problems with ground stalling.

What is more important to know about a hydraulic motor “Nominal Rated Torque or Peak Rated Torque”!! Please Google this as “Nominal Rated Torque” is the most important torque rating you should know about any hydraulic motor. In short, it is the optimum range that a hydraulic motor can run at all day every day without overheating and causing damage. “Peck Rating torque” is like redlining your car engine and you wouldn’t do this to your car engine!!

Designed to be compatible with all makes/models of excavator

NZ Stirrers Mixers are designed with interchangeable hitch plates. This allows you to into-change between different excavator’s models and or sizes excavators.

Manufactured in New Zealand

These innovative attachments are manufactured from high tensile, abrasion-resistant bisalloy steel. Precision-designed to help extend the operating life of plant and reduce machinery down-time. All bearings and seals are carefully situated to avoid wear and tear from high abrasion material like liquid cement grout, gritty sandy soils, stones, timber, and ground pressure that can cost you dearly in down time.

“Mass Ground Stabilising Equipment”

Unique – World first design – 10-metre-long main shaft with 3 Interchangeable mixing heads.

Custom designed and hand built to each customers exact Project requirements.

High quality “Italian” Hydraulic Drive Motors – 2 speed – high torque – with reverse.

All Hydraulic motors are extremely powerful with ground stalling of your mixing head a thing of the past.

If you’re looking for Mass Ground Stabilizing Equipment that can be customized to meet your project needs and then hand built in New Zealand, and delivered anywhere in the world, then you’ve come to the right company.

NZ Stirrers attachments are all custom-built and come on a custom cradle fixed to an open top shipping container, securely housing both mixing heads during transport. The open top shipping container has a cradle system for the main shaft designed to make it quick, easy, and safe to change mixing heads over on-site.

What makes our Mixers unique is the fact that we can custom make them to any length you want up to 12 metres long. All our Mixers come with interchangeable mixing heads.

No other Mass Ground Stabilizing Equipment has the ability to interchange mixing heads to accommodate for different ground conditions eg hard to stiff ground – semi soft grounds to dredging mud/sludge. This now gives you the ability to stabilize a wider range of projects that might have multiple different ground conditions over the site area. If ground conditions change, simply unscrew the CFA Coupler connection, and reconnect up to the mixing head you require. As easy as that!

Another unique feature with NZ Stirrers Mass Ground Stabilizing Mixing Equipment is our ability to spec a wide range of high-quality Italian made hydraulic drive motors to suit your requirements. Our drive motors start from 90,000Nm of torque going up to 120,000Nm of Nominal Rated Torque. All drive motors including reverse and a sourced directly out of Italy and flown back to New Zealand.

As your Mass Soil Ground Stabilizing Mixers are attached to a large excavator. This allows for the excavator to be used for bulk excavation on site if needed.

The length of your Mixer “main shaft” will be your next decision to make as we customize your Mixer to exactly what you need. Being able to choose between a 5-metre-long shaft right up to a 10-metre-long shaft, (add the mixing head) lets you get the right equipment you need for the job. Our Engineers will then custom design and build your mixer to meet your exact requirements. Strengthening will be done to accommodate which drive motor you have chosen to use. These are extremely powerful drive motors, and everything needs to be reinforced to handle the loads placed on the shaft from the torque. Every Mixer is custom designed and meticulously hand built to your exact requirements.

You are welcome to fly out to Auckland, New Zealand to view your new Mass Soil Ground Stabilizing Mixer before we Sea freight it to your place of origin. The Open-Top shipping container is part of the whole package and is yours to keep. This will allow you to easily move your Mixer from place to place by truck, rail, or sea.